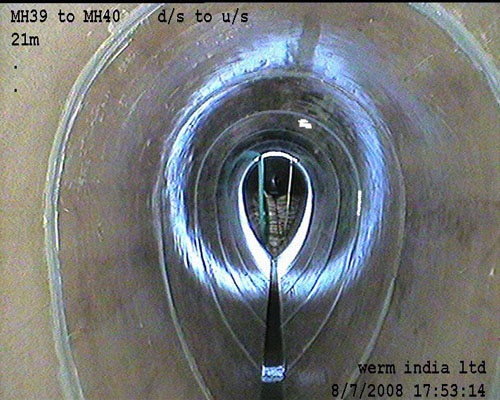

As one of the fastest growing economies, development of modern public infrastructure including underground water and sewerage supply network is on rapid growth in India. Since most of this network is laid underground, any future maintenance activity that comes up due to some workmanship defects is very expensive. Such unnecessary expenditure can be avoided by proper/intrusive inspection of such assets before commissioning. Since most such assets are non-man entry pipes, manual intrusive inspection is not possible and hence robotic conditional assessment survey becomes a necessity. Further, maintenance activities involving sewer works often involve manual intervention causing unnecessary risk to human lives. Using robots to perform such tasks can save such risks o human lives and put an end to manual scavenging once and for all.

Robotic Inspection methodologies eliminates the risk to human life. The data generated using such inspections can be integrated with existing GIS data of the ULB which helps in future asset management. The generated inspection reports can be used as a reference to plan any future regular maintenance activities. Such inspections can also be done in running sewer pipelines to ascertain their current condition and identify & locate faults if any. Old & running pipelines can be graded on a scale of 1-5 (as per internationally accepted WRc norms) which helps in establishing the pipe’s RUL (Remaining Useful Life).